Semiconductors For Self-Reliance In Aerospace Manufacturing

The initiative on Self-reliance and Atmanirbhar Bharat has propelled the Indian defence industry towards higher pursuits and undertaking ambitious projects. The Indian defence industry, specifically the aerospace industry, has paved its way ahead in the last few years by investing in producing aircraft parts, manufacturing components, and developing systems. The future is bright for the industry with large scale manufacturing already in progress for the Light Combat Aircraft (Tejas), Advanced Light Helicopter (Dhruv), the Light Combat Helicopter (Prachand), Weaponised ALH (Rudra), Light Utility Helicopter (LUH), light passenger aircraft Hindustan-228, trainer HTT by Hindustan Aeronautics Limited (HAL), Medium lift transport Aircraft C-295 (manufactured by Tata Advanced Systems Limited), and large sized airframe parts of Chinook, F-16, Apache etc., by few other private companies. The development of Advanced Medium Combat Aircraft (AMCA) by Aeronautical Development Agency (ADA) and SARAS light transport aircraft by NAL is also under progress. In addition, many Indian firms are already into development of drones and unmanned aerial vehicles for use in military as well as civilian purposes.

The Indian industry has developed adequate capability for manufacturing and fabricating various aircraft parts. The indigenous content of the LCA in 2018 was 59.7% by value and out of 344 LRUS (Line Replaceable Units), 210 were produced indigenously [1]. This content would grow in future with efforts towards indigenisation. Though minor details of indigenous contents are not available, it is well known that the major share is for the airframe and mechanical parts. For avionics components, modern electronic systems and niche technologies, the indigenous capability is still a work in progress. The cutting edge for any modern fighter aircraft or other military aircraft lies in its modern avionics and advanced systems, better than the adversary’s platforms. The development in technology at rapid pace, also necessitates continuous upgradation of these systems to overcome obsolescence and possessing superior technologies than the adversary. At present, the Indian defence industry is not fully independent and relies on foreign support in terms of technology, design, components, and spares for the electronic systems. The key to this development and upgradation lies in possessing indigenous capability for avionics systems and components which have indigenous parts, mainly the chips or microprocessors.

Most of the electronic devices we use are imported. Electronic goods account for nearly 10% of total imports by India, second only to petroleum products and almost same as gold imports. One electronic equipment that is always imported is the microprocessor, which is the ‘brain’ of any electronic device. A microprocessor is an integrated circuit (IC) fused on a semiconductor chip. Every electronic device requires these semiconductor-based microprocessors, which range from simple household devices such as washing machines, mobiles, microwaves, television sets and also used in medical equipment, automobiles, aircraft systems and space missions. Only few companies in the world have capability to manufacture microprocessors. Unless we develop the capability to produce these microprocessors and specially which are required to be configured for military platforms, we cannot truly achieve self-reliance in the field of defence and aerospace manufacturing.

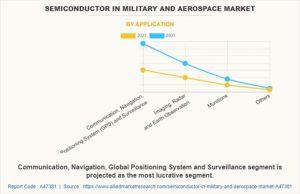

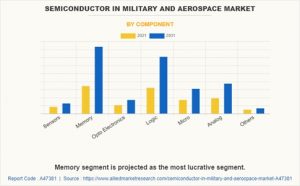

Semiconductors are vital part of electronics systems and components. Furthermore, in military and aerospace sector, semiconductors are used in manufacturing of numerous devices & systems such as communication & navigation systems, safety equipment, engine & flight control systems, missile systems, weapon systems etc. The global semiconductor in military and aerospace market size was valued at $6.3 billion in 2021, and is projected to reach $12.9 billion by 2031, growing annually at the rate of 7.6% from 2022 to 2031. The semiconductor requirement in military and aerospace market is driven due to requirements for aircraft upgradation, modernisation programmes and use of radiation tolerant semiconductor components [2].

Why is Semiconductor Important?

A semiconductor is a substance which possesses the properties of both conductor and an insulator. It can conduct electricity under certain circumstances but not always. This makes semiconductor a good medium to use electricity in a controlled manner as and when required. Common semiconductor materials include silicon, germanium, gallium arsenide, etc., and silicon is the most influential in commercial applications among various semiconductor materials. A semiconductor based integrated circuit is a combination of active components such as transistors, diodes and passive components such as resistors and capacitors, which are integrated on a single semiconductor chip or several small semiconductor wafers, to complete a specific circuit or a system function. This makes micro miniaturisation possible for the electronic components with low power consumption, intelligence and high reliability [3]. Semiconductors are therefore very useful in various defence applications such as Radars, Electronic Warfare (EW), Communication Systems, Power plants, Mission and Weapon Computers, Cyber Weapons and Autonomous systems. The requirement in aerial platforms is more; however, they are also important for modern weapons and sensors required by the land forces and for the naval platforms. Indigenous development of semiconductors will therefore not only provide a quantum jump in achieving self-reliance in developing these systems but will also be useful for civilian applications and result in huge reduction in imports of electronic components.

There are a very few firms in the world having chip manufacturing capability and are mostly limited to a few East Asian countries. The semiconductor industry is dominated by companies from Taiwan, USA, South Korea, China, Japan, and the Netherlands, where the manufacturing system has government support, developed infrastructure and economies of scale. There was extreme shortage of chips during the Covid pandemic, which seriously affected various industries in the world. This made other countries realise importance of the semiconductor supply chain and consider developing capability to manufacture chips, for reducing imports and improving self-reliance. India is planning to spend around $30 billion to develop the semiconductor supply chain ecosystem [4].

![]()

The USA enacted CHIPS and Science Act, which was signed into law by President Joe Biden on August 9, 2022. America invented the semiconductor, but today produces only about 10 percent of the world’s supply; none of the most advanced chips, and relies on East Asia for 75 percent of global production. The CHIPS and Science Act will boost American semiconductor research, development, and production, ensuring U.S. leadership in the technology that forms the foundation of everything from automobiles to household appliances to defence systems. US companies have announced nearly $50 billion in additional investments in American semiconductor manufacturing, bringing total business investment to nearly $150 billion [5]. A White House report has emphasised the initiative to lower the manufacturing costs, create jobs, strengthen supply chains and counter China. The strategic importance of semiconductor manufacturing and supply chain is therefore evident.

The Semiconductor Supply Chain

The semiconductor industry is based on a model in which fabrication, design and development is distributed among different companies and their subsidiaries around the world. Foundry companies like TSMC (Taiwan), and Global Foundries (a multinational firm headquartered in USA) are involved only in manufacturing the wafers also called the ‘fabs’. The first foundry TSMC is the largest independent manufacturer of silicon components in the world. Fabless semiconductor companies like AMD, Qualcomm, Broadcom, and Nvidia (all US companies) outsource production to a third-party fabrication plant and only design the device. The term ‘fabless’ means that the company designs and sells the hardware and semiconductor chips but does not manufacture the silicon wafers, or chips, used in its products; instead, it outsources the fabrication of ‘fabs’ to a manufacturing plant or foundry. China is the third largest nation in the fabless segment and 10 Chinese companies are amongst the top 50 fabless companies. Integrated Device Manufacturers (IDMs) such as Intel (US) and Samsung (South Korea) manufacture (in-house), design and as well as sell integrated circuit products [4] [6].

Complexities of Semiconductor Manufacturing

The process of making semiconductor chips involves several complex equipment and different steps which are required to be repeated to create layers in a chip. Depending on number of layers which could be as many as 100, the steps must be repeated as many times. The wafers of silicon extracted from sand are transformed into transistors which form the base of a group of circuits called chips. The wafers are coated with photosensitive chemicals and light resistant materials. During the second stage lithography is performed, where coated silicon wafers are exposed to UV light. This process makes it possible to build hundreds of chips on a single silicon wafer. The next step involves the use of ionic gasses to modify the conductive properties of the layer, by adding some impurities and then finally the metal links are laid down between transistors, thereby creating one complete layer. All these steps are to be repeated to create subsequent layers. The most critical part of semiconductor production is Electronic Device Automation (EDA), which designs the chip before it is manufactured. It is a costly process as every end product demands different semiconductors and hence a different software automation for each product. This complex process requires skilled engineers and vast R&D. Manufacturing a chip is therefore a complex procedure which takes considerable amount of time to turn the raw silicon into the final chip. Further, it requires expensive factory equipment and involves a complex network of companies which produces or designs them and those who develop and supply the technology, materials and machinery required. This network forms the supply chain for semiconductor production [4].

Disruptions in Supply Chain

Neon is required for lasers used in lithography process. 70 percent of Neon comes from Ukraine and is produced by two Ukrainian companies only- Ignas and Cryin. The Russia Ukraine war has therefore worsened the global chip shortage. Moreover, Palladium is required for catalytic converters in the exhaust of automobiles, 35 percent of which comes from Russia. With the ongoing war, the semiconductor industry is likely to be affected as the demand for chips by automobile manufacturers may get reduced [4]. Growing Taiwan and US tensions with China have further brought serious challenges to the semiconductor industry. Taiwan is a major producer of chips, which are used in almost everything from cars and smartphones to fighter jets. During the annual G7 leaders meet on May 19, 2023, the United States has been increasingly urging its allies to counter China’s chip and advanced technology development. Chipmakers are also looking at Japan as an option wherein investments would be required. A diversified, stabilised, and resilient supply chain for economic security has been emphasised by Japan and important topic of discussion at the G-7 [7]. Diversification of semiconductor manufacturing is therefore in the interests of all industrially developed and developing nations.

The Indian Scenario

“A nation without silicon (technology) is like a person without heart”. This was stated by the executive director of Manufacturers’ Association for Information Technology who was part of initial discussion on a project spearheaded by the Council of Scientific and Industrial Research (CSIR). The project was conceptualised in 2009, to develop an India Microprocessor, a public-private program in collaboration with the Ministry of Information Technology (IT). However, the need to develop microprocessor in India was questioned, as it was opined by the ministry officials that, there were enough good and cheap ones available in the market and even many other countries had not developed a microprocessor of their own [8]. This argument and thought process probably led to loss of the initiative. Some success was however, achieved subsequently in 2018-19, when IIT, Madras and IIT, Bombay developed indigenous microprocessors called ‘Shakti’ and ‘Ajit’ respectively.

India’s dream of becoming global leader in the semiconductor sector was conceived way back in 1976. The time was appropriate as Taiwan, Israel, Korea and even China were nowhere near being the semiconductor powerhouses that they have now become. The Semiconductor Complex Limited (SCL), now called Semi-Conductor Laboratory at Mohali was established in 1983 under the Ministry of Space. Its goal was to design and manufacture leading edge circuits and electronics for the Indian electronics industry. However, a massive fire in 1989 had disrupted the initiative and in 1997 the facility was restarted. In 2006, it was restructured as a research & development centre and renamed to “Semiconductor Lab”. As part of government’s $10 billion incentive package to build a semiconductor ecosystem in the country, efforts are being made to modernise and commercialise the brownfield semiconductor chip fabrication facility of SCL through a joint venture. The only IDM facility of India, SCL is now under Ministry of Electronics and IT (MeitY) and is being opened up as a commercial fab for wider participation by Indian semiconductor design companies [9] [10]. Centre has planned to invest 2 billion dollars in SCL, as per the latest reports.

MeitY has established Digital India Corporation (earlier known as ‘Media Lab Asia’), a not-for-profit company w.e.f. Sep 8, 2017. The ‘India Semiconductor Mission (ISM)’, is an independent business division within Digital India Corporation, to drive India’s strategies for developing semiconductors and display manufacturing ecosystem and enable India to emerge as a global electronics design and manufacturing hub. The ISM is authorised to negotiate with the applicants under the semiconductor and the display fab scheme to decide the appropriate technology mix, applications and capacity to propose the structure and quantum of fiscal support for the selected applicant. It has plans to formulate a strategy for developing semiconductors and display design eco-system and manufacturing facilities, develop a trusted semiconductor supply chain, including raw materials, specialty chemicals/ gases, manufacturing equipment and foundry services. ISM will enable cutting-edge research in semiconductors and display industry including evolutionary and revolutionary technologies through grants, global collaborations, involvement of academic/research institutions and the industry. The scheme for setting up of Semiconductor Fabs, Display Fabs, Compound Semiconductors / Silicon Photonics / Sensors (including Micro Electro Mechanical Systems-MEMS) Fabs / Discrete Semiconductors Fab and Semiconductor ATMP / OSAT facilities in India, shall extend fiscal support to the chosen industry, up to 50% of project cost [11].

Outsourced Semiconductor Assembly and Test (OSAT), which is also referred to as Assembly, Testing, Marking, and Packaging (ATMP) units, plays a crucial role in semiconductor manufacturing as they package and test the silicon chips made at the foundries before they are shipped to the market. Tata Electronics Private Limited (TEPL), a greenfield venture with expertise in manufacturing precision components, is planning to set up an Outsourced Semiconductor Assembly and Test (OSAT) facility. Earlier, Tata Group was also planning to set up a $300-million semiconductor manufacturing facility. Apart from Tata, with ISM support of Rs 76,000 crore, over half a dozen companies have shown interest in putting up ATMP units in India. ATMP is critical for India’s Semiconductor Mission and overall semiconductor ecosystem as no chip can be used in a product without going through the packaging and testing process [12]. In July 2022, Sahasra Semiconductors announced to set up a memory chip assembly, test, and packaging unit at Bhiwadi, with a total investment of Rs 750 crore. As per an update on its website, the firm completed sample manufacturing in March 23 and is starting mass manufacture in May 2023. Even Tamil Nadu semiconductor manufacturing company Polymatech had announced plans to invest $1 billion to expand its chipset manufacturing and packaging facility. In October 2022, it has kickstarted the production of Opto-semiconductors (used in lighting, medical and food sanitization applications) and memory modules which are an integral part of all major electronic systems [13]. Vedanta and Taiwan’s Foxconn have also signed an MoU in October 22 to set up semiconductor and display production plants with investment of 20 billion dollars at Ahmedabad. The firm aims to start production after two years [14]. The recent thrust for developing semiconductor manufacturing in India, will show results in next few years, provided the momentum is maintained.

Importance of semiconductor manufacturing and a stable supply chain has been realised and recognised by most nations, as it was discussed in the G-7 meeting and also led to US enacting a law related to it. India and the USA launched iCET (the Initiative for Critical and Emerging Technologies), under which semiconductor fabrication in India was also to be supported. The US Secretary of Commerce Gina Raimondo travelled to India in March 2023, to sign the Memorandum of Understanding which is based on the semiconductor supply chain and ‘Innovation Partnership’. However, India (and naturally China) opposed the CHIPS act and asked for clarifications in the World Trade Organisation, as it affects the level playing field for other nations. [15].

The global semiconductor market is projected to reach over 1 trillion dollars by 2030 as compared to $590 billion in 2021, as per a McKinsey report. India’s semiconductor market will be among the world’s fastest-growing and is forecast to grow from $15 billion in 2020 to $110 billion in 2030. The Indian government has estimated a $550 billion budget in this sector in 2023 [16]. The semiconductor industry therefore has enormous economic, technological and geopolitical significance for India.

Conclusion

It is evident that capability to manufacture semiconductors is crucial for India to achieve self-reliance in electronics production, reduce import costs, progress its indigenous defence industry and maintain strategic autonomy. Despite efforts to establish semiconductor manufacturing capability, India could not do so for various reasons. This has affected its electronic industry, industrial capability and now restricting efforts to indigenise defence products. Manufacturing semiconductors is also not easy due to high investments, complex machinery, a complex supply chain and required technology. However, it is not impossible as smaller countries have been able to achieve it. The efforts by government have vitalised this industry by bringing in more private players who are successful in delivering the results. India has no dearth of technical expertise and capability. To achieve self-reliance in defence production and aerospace manufacturing, all it requires is a firm plan, dedicated effort, unhindered-unwavering support, and sound backing from the government in realising the ‘Semiconductor Dream of India’.

***************************************************************************************************************************

References

- ‘Indigenous content of Tejas 59.7% by value & 75.5% by numbers’, The Economic Times, July 14, 2018, https://economictimes.indiatimes.com/news/defence/indigenous-content-of-tejas-59-7-by-value-75-5-by-numbers/articleshow/55498923.cms

- ‘Semiconductor in Military and Aerospace Market’, Allied Market Research, Global Opportunity Analysis and Industry Forecast, 2021-2031, February 2023, https://www.alliedmarketresearch.com/semiconductor-in-military-and-aerospace-market-A47381

- The difference between Chips and Semiconductors and Integrated Circuits’, January 1, 2022, https://www.shunlongwei.com/the-difference-between-chips-and-semiconductors-and-integrated-circuits/.

- ‘Why Semiconductor Production is Hard and only a few Companies Produce it?’, by Palak Ghai, Startup Talky, July 4, 2022, https://startuptalky.com/why-few-companies-produce-semiconductor/#:~:text=The%20process%20of%20making%20semiconductor,repeated%20in%20the%20same%20number

- The White House, ’FACT SHEET: CHIPS and Science Act Will Lower Costs, Create Jobs, Strengthen Supply Chains, and CounterChina’, August 09, 2022, https://www.whitehouse.gov/briefing-room/statements-releases/2022/08/09/fact-sheet-chips-and-science-act-will-lower-costs-create-jobs-strengthen-supply-chains-and-counter-china/

- ‘What Are “Fabless” Chip Makers? byThe Investopedia Team, Updated September 29, 2022, https://www.investopedia.com/ask/answers/050615/what-are-fabless-chip-makers-and-why-are-they-important-semiconductor-market.asp

- ‘Chipmakers look to Japan as worries about China grow’, by Reuters, May 18, 2023, https://edition.cnn.com/2023/05/18/tech/chipmaking-japan-china-g7/index.html

- ‘Why a made-in-India chip remains chimeric’, by Seema Singh, Livemint, March17, 2010. https://www.livemint.com/Home-Page/P8hJk0uMYmajN0tFph692K/Why-a-madeinIndia-chip-remains-chimeric.html

- ‘When India’s dream of becoming Semiconductor Powerhouse was shattered’, by Vijay C Roy, The Tribune, Oct 08 2022, https://www.tribuneindia.com/news/punjab/when-indias-dream-of-becoming-semiconductor-powerhouse-was-shattered-439130

- SCL Mohali Modernization to Help Advance India’s Semiconductor Goals, by PIB, EE Times, 16 Feb 2023, https://www.eetindia.co.in/scl-mohali-modernization-to-help-advance-indias-semiconductor-goals/

- ‘Indian Semiconductor Vision’, https://dic.gov.in/index.php/divisions/india-semiconductor-mission

- ‘ What will the Tata Group do in the Semiconductor Biz?’, by Nidhi Singhal, Business Today, 09 Dec 2022, https://www.businesstoday.in/latest/corporate/story/whats-outsourced-semiconductor-assembly-and-test-osat-that-tata-group-plans-to-venture-into-355718-2022-12-08

- ‘ In a first, Polymatech rolls out Made In India Semiconductor Chips’, Content Media Solution October 11, 2022 https://contentmediasolution.com/business/in-a-first-polymatech-rolls-out-made-in-india-semiconductor-chips/

- ‘Vedanta, Foxconn to invest $19.5 billion in India’s Gujarat for Chip, Display Project’, by Munsif Vengattil and Aditya Kalra, Reuters,13 Sep 2022, https://www.reuters.com/world/india/vedanta-foxconn-sign-mou-with-modis-home-state-20-bln-chip-foray-2022-09-13/

- ‘India objects to US hypocrisy on CHIPS act in WTO’, by Shubham Bajpai, TFI Post, April 04, 2023, https://tfipost.com/2023/04/india-objects-to-us-hypocrisy-on-chips-act-in-wto/

- ‘Why Semiconductors are Central to Geopolitics and where India stands in the Power Matrix’, News Laundry, by Priyank Shukla, May15, 2023, https://www.newslaundry.com/2023/05/15/why-semiconductors-are-central-to-geopolitics-and-where-india-stands-in-the-power-matrix

Disclaimer

The opinions expressed in this article are the author’s own and do not reflect the views of Chanakya Forum. All information provided in this article including timeliness, completeness, accuracy, suitability or validity of information referenced therein, is the sole responsibility of the author. www.chanakyaforum.com does not assume any responsibility for the same.

Chanakya Forum is now on . Click here to join our channel (@ChanakyaForum) and stay updated with the latest headlines and articles.

Important

We work round the clock to bring you the finest articles and updates from around the world. There is a team that works tirelessly to ensure that you have a seamless reading experience. But all this costs money. Please support us so that we keep doing what we do best. Happy Reading

Support Us

POST COMMENTS (0)